In the console area at the bottom of the MPLab X window you should

see the following activity in a tab labeled "SNAP".

*****************************************************

Connecting to MPLAB Snap...

Currently loaded versions:

Application version............00.03.23

Boot version...................01.00.00

Script version.................00.04.48

Script build number............7acb7c9d66

Tool pack version .............1.7.510

Connecting to MPLAB Snap...

Currently loaded versions:

Boot version...................01.00.00

Updating firmware application...

Connecting to MPLAB Snap...

Currently loaded versions:

Application version............00.04.50

Boot version...................01.00.00

Script version.................00.04.48

Script build number............7acb7c9d66

Tool pack version .............1.7.510

Target device PIC18F25K22 found.

Device Id Revision = 0x5

Calculating memory ranges for operation...

Erasing...

The following memory area(s) will be programmed:

program memory: start address = 0x0, end address = 0x273f

program memory: start address = 0x7500, end address = 0x7fff

configuration memory

Programming/Verify complete

If you get an error while programming:

- Make sure that the development board is powered on with

the USB mini cable.

- Make sure that you have configured MPLab correctly.

Subsystem tests

You are going to work through each of the subsystems on your development

board and test them one at a time. After soldering in a new component,

it would be a good idea to re-run all the subsystem tests to check that

you did not create a problem with the added component. This type

of testing is called regression testing.

While testing you PIC may hang for a variety of reasons. You can reset

the PIC processor by pressing the RESET button located at the top of the

development board. You will know that you have

reset the PIC when you are greeted by the splash screen:

Dev'21 Board

Test Program

Spring 2021

Colorado School of Mines - EENG 383

When performing a reset, it's normal to get some garbage characters at

the start of the splash screen - this is just the baud-rate generator

inside the USART subsystem converging to proper frequency.

Test #1 - Test RS232 communication

Soldering:

No additional through-hole components should be soldered to the

development board in this test.

Procedure:

You have already downloaded the test application written to

exercise most of the modules on the development board, now it's

time to use this application to complete testing of your board.

Let's start by running the test application using the following

steps.

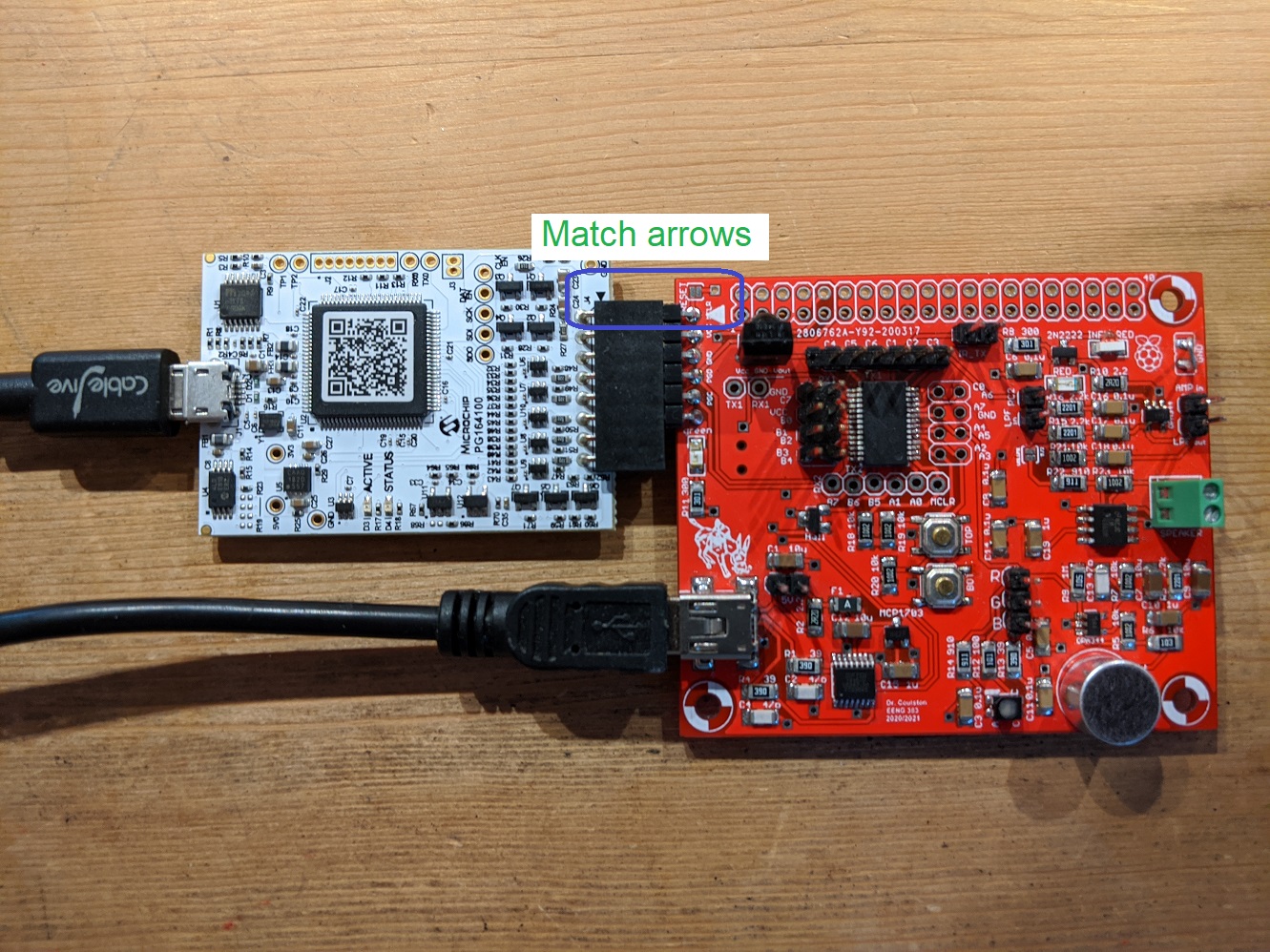

- Unplug both the development board and the SNAP programmer from your PC.

Since the PIC18F25K22 is a flashed based part, its non-volatile memory will

hold the test application until you overwrite it in lab 2. Set the

SPAN programmer aside, you will not need it again in this lab.

- Connect the development board to the PC through the mini-USB connector.

If the sound on your PC is turned on, the PC will make a chime when the

development board is plugged in.

- Find out which COM port is being used by the FT230 chip. You

can do this is a multitude of ways, one of which is by running

Brandon's COM port Sniffer,

Take a screen shot of Brandon's COM port Sniffer by pressing Alt-PrtSc.

This keypress sequence captures the active window to an image buffer. Paste

the image buffer into a document using Ctrl-v. Use this as your answer to Test #1

- Launch PuTTy

Connection type: Serial

Serial line: COMx (where x is the port associated with the FT230

Speed: 9600 (the default)

Open

- Type "?" in the PuTTy window.

This test hex file will bring up an interactive terminal application on

virtual COM port. You should see:

==============================================================

?: help menu

o: k

Z: reset processor

z: clear the terminal

b: Button test.

l: Low pass filter (LPF) test.

a Amplifier test.

d: ir Decoder test.

m: Microphone test

c: rgb Color test.

t: ir led Transmitter test.

h: Hall effect sensor test.

i: Initialize sd card.

s: read/write SD card.

==============================================================

The prompt, "CMD>" is telling you that the PIC is waiting for a

command corresponding to one of the letters in the leftmost column.

Anytime that you want see the menu, press "?". The PIC is not

a very fast processor and if you press two keys in quick succession,

you may hang the processor - sad but true. If this happen reset the

PIC using the reset procedure outlined in the Subsystems tests section

just below.

For the time being it would be a good idea not to explore these options

as some of them require you to solder and configure jumper wires.

Test #2 - Test CPU

Soldering:

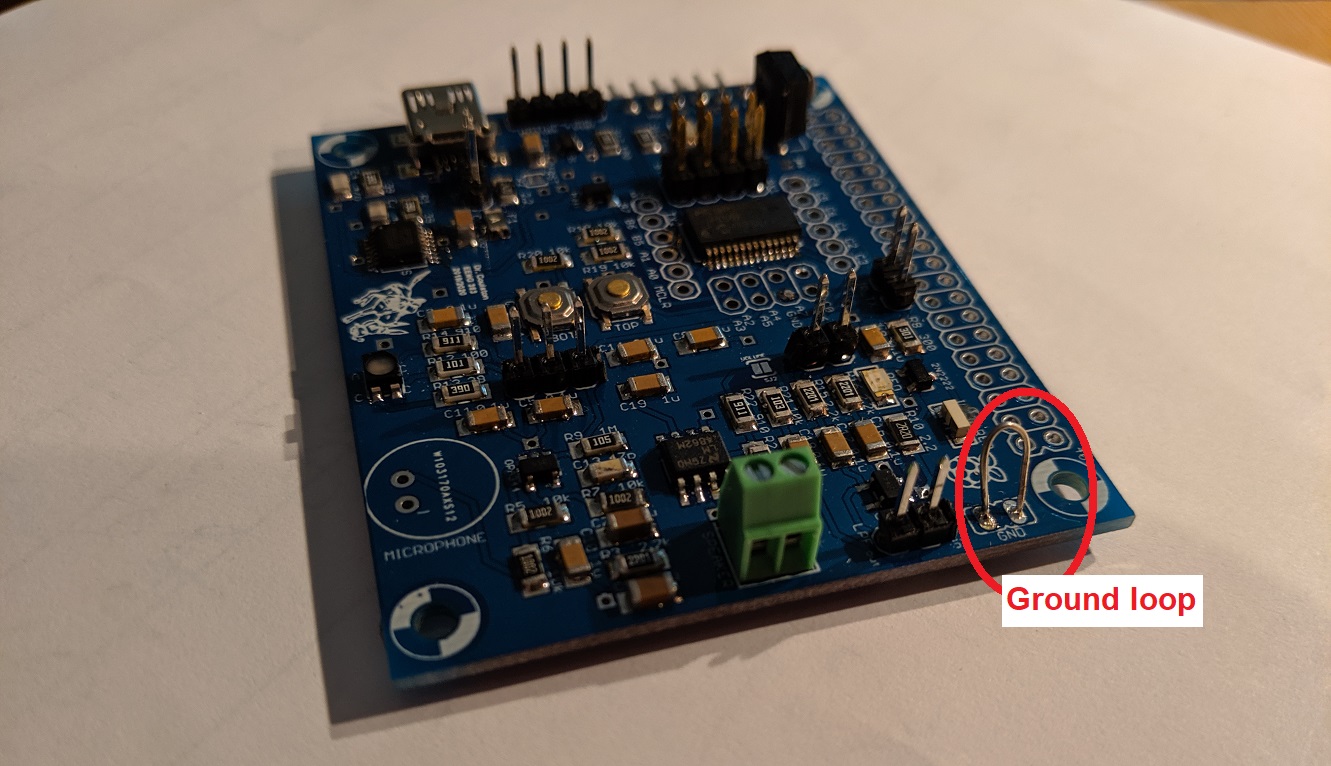

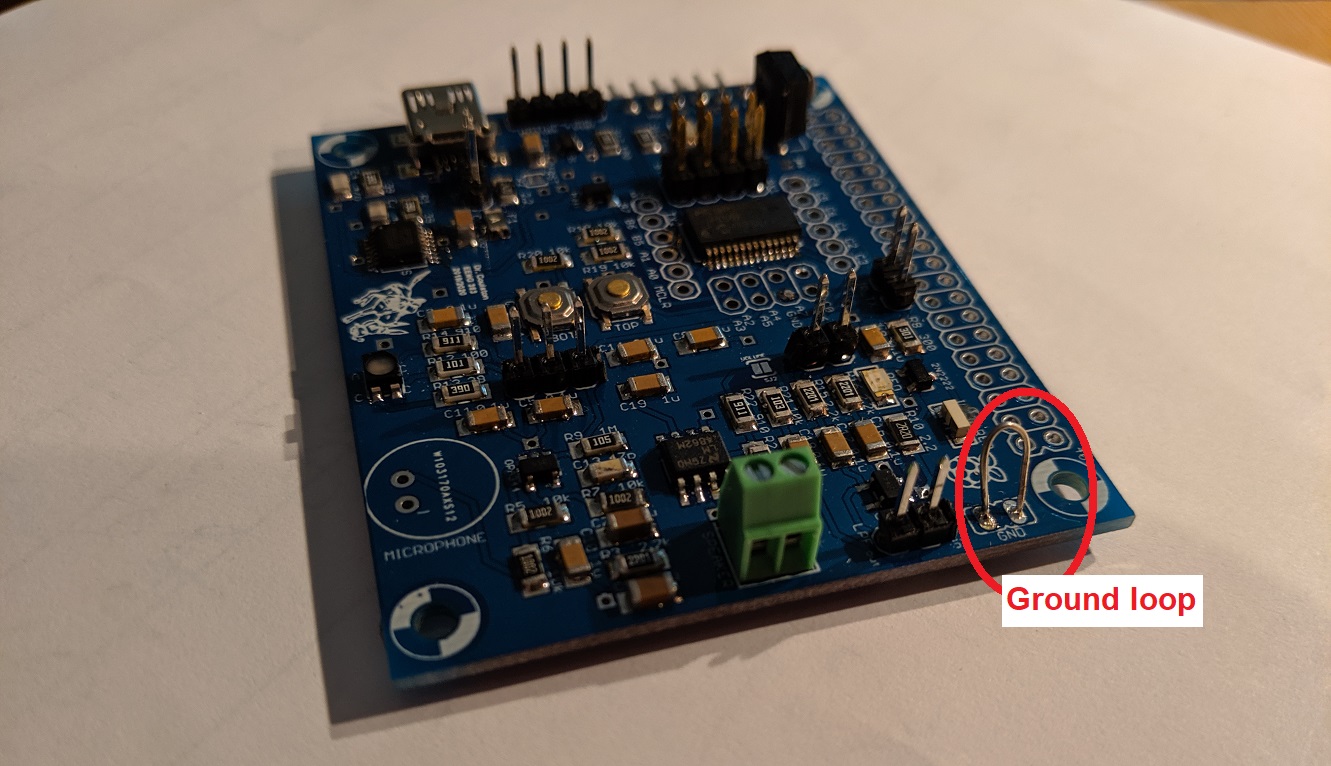

Take a moment and solder ground loops to the PCB. I've found that the

leads of a through hole resistor make great wire for the ground loop -

don't feel bad trashing a resistor for this, they are cheap. When

complete, your ground loops should look like the image

below (note this is a picture of a partially assembled board, yours will

be complete). Ground loops allow you to attach the ground lead clip of an

oscilloscope to your board - super handy.

Procedure:

Once you have the ground loop in, let's test them out by checking if

the PIC is running. To do this follow these oscilloscope instructions.

Note, you will have to remove the "gripper" form the end of the scope

probe and insert the sharp end of the of the probe into the break-out

holes around the PIC.

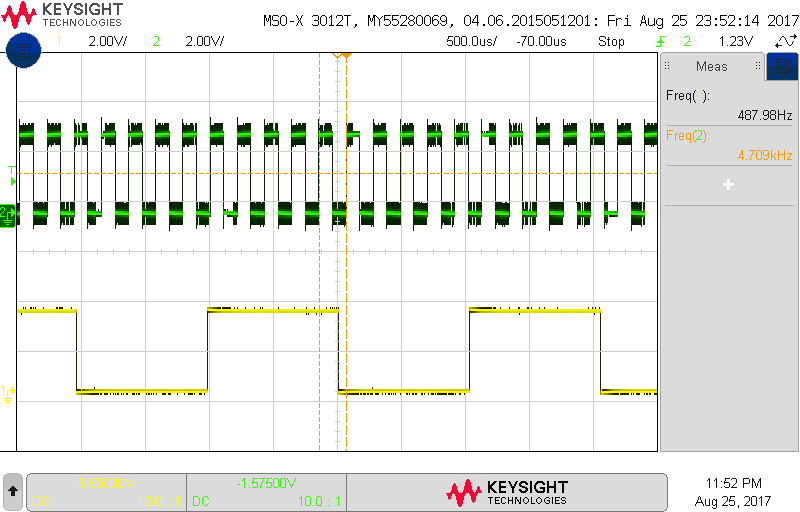

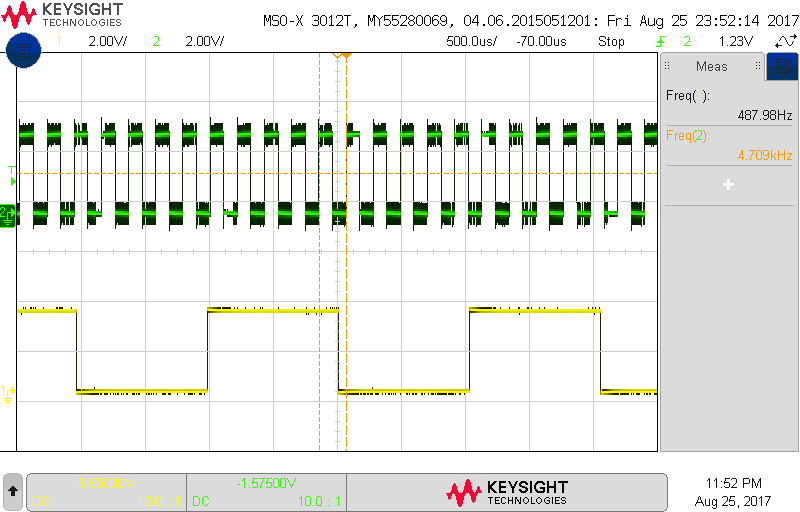

| Ch1 probe | RB6

|

| Ch2 probe | RB7

|

| Ch1 ground clip | Dev board ground loop

|

| Horizontal (scale) | 500 us

|

| Ch1 (scale) | 2V

|

| Ch2 (scale) | 2V

|

| Trigger mode | Auto

|

| Trigger source | 1

|

| Trigger slope | ↑

|

| Trigger level | 1.2V

|

Make sure that

- Aligning Ch 1 and Ch2 on the second lowest reticules

on their respective halves of the screen,

- Align the horizontal position at the second left-most reticule,

- Clear all menus off the bottom of the screen

[↑Back]

- Since the two channels are not synchronized, you may need to

tell the oscilloscope to stop refreshing the screen. To do this:

Run Control → Run/Stop (the button will illuminate red)

To resume refreshing the screen press the Run/Stop button again

causing the button to be illuminated green.

When you do this you should see something similar to the following. Note

that the frequencies will be different from that shown in the image

below. Channel 1 will be around 515Hz. Channel 2 should be around 5.2kHz.

Capture this oscilloscope trace onto a USB drive and then use this image

as the answer to Test #2.

Test #3 - Test Terminal

Soldering:

No additional through-hole components should be soldered to the development

board in this test.

Procedure:

Since you already got the menu to work, this test is a little silly,

but hey the menu options are there. So go ahead and

press "o", the PIC should respond

with the letter "k". This is the most basic test of the PICs

ability to read and write information over its universal

asynchronous synchronous receive transmit (USART) port.

You can also experiment with "z" and "Z" to clear the screen and reset

the processor. Note that the "Z" reset is called a soft reset because

it occurs from within code. If the PIC is hung, then this option will

not be available and you will have to press the reset button at the top

of the board.

The "Z" function performs a reset of the PIC. This is handy when you

may have messed up some registers and just want them back to their

default values. Make a screen shot of the PuTTY window right after

pressing the "Z" key as your answer to Test #3.

Test #4 - Test Buttons

Soldering:

No additional through-hole components should be soldered to the development

board in this test.

Procedure:

When you press "b" at the command prompt, you will see the following

message:

CMD> b

Button test

Press any key to exit.

Press the upper, lower, or both buttons.

Each time one or both button is pressed a message will appear in

the terminal.

Clear the PuTTY window using "z" and then enter the button test

function. Press the upper button three times, the lower button

once, then both buttons once. Then make a screen shot of the PuTTY

window as your answer to Test #4. You have to fast on that last

pair button press. Keep at it, you'll get it!

Test #5 - Test Hall effect sensor

Soldering:

No through-hole components should be soldered to the development board

in this test.

Procedure:

When you press "h" at the command prompt, the PIC will test the

Hall effect sensor. A hall effect sensor is a device which outputs

a voltage proportional to the magnetic field present at the ICs

surface. When pressed you should see the following:

CMD> h

Hall effect sensor test

Wave north and south poles of magnet above Hall effect sensor.

Press any key to exit.

Placing the north or south facing magnetic field of your magnet

will elicit a message on the terminal.

Clear the PuTTY window using "z" and then enter the Hall effect

function. Create at least 3 magnet encounters with the sensor and

show at least one change from North to South pole. Then make a screen

shot of the PuTTY window as your answer to Test #5.

Test #6 - Test Microphone

Soldering:

No through-hole components should be soldered to the development board

in this test.

Procedure

When you press "m" at the command prompt, the PIC will test the

microphone. The microphone continuously provides the amplitude of the

sound wave to the PIC which when it samples the sound wave converts this

amplitude into an 8-bit value between 0 and 255. This function provides

16 samples, each 100uS apart. The samples are collected as soon as

you press a key (after pressing "m"). This allows you to start your

whistle and get it going before it is sampled. An example of the

test output is shown below.

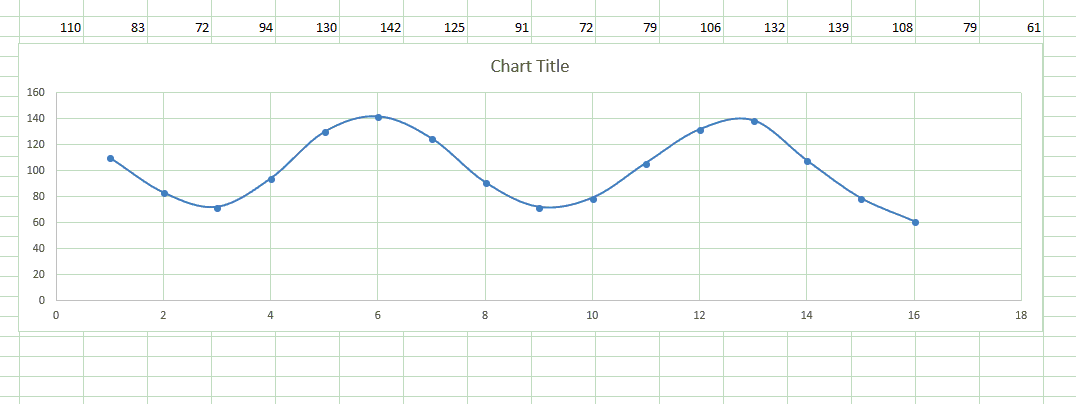

CMD> m

Microphone test

While whistling near the mic, press any key.

Sampled every 100uS.

MIC:

73 44 65 127 176 176 121 59 35 66 127 171 152 89 33 22

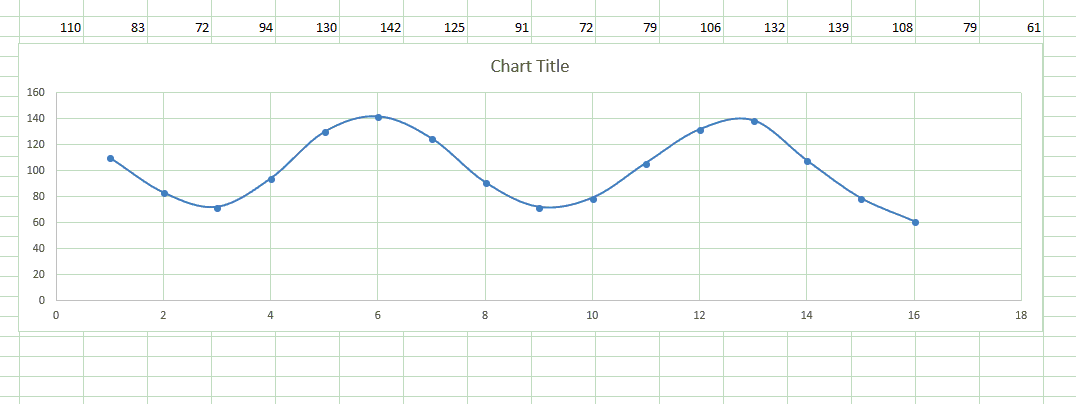

The output looks a little random, so you will want to plot the samples in Excel

in order to make more sense of them. The image below shows the resulting

plot and definitely reveals the sinusoidal nature of a whistle.

Since we know the samples are taken every 100us, the period of my whistle

is about 700us which corresponds to 1.4kHz, a reasonable value for a

whistle.

The samples are biased around the mid range value of 128. The louder

your whistle, the higher the amplitude of the waveform. If you whistle

too loud or too close to the microphone, you will saturate the microphone

output at 0 and 255. When plotted saturated volume will appear as flat peaks.

The answer for this test requires several steps:

- Whistle near the MIC using the "m" function to collect 16 samples.

- Select the sample in PuTTY (this automatically puts them into the

copy/paste buffer.

- Open Excel

- Paste the microphone samples into a cell.

- Use the Data → Text To Columns function to separate the 16

values into individual cells. You will need to select Delimited, Space,

General as the steps in the Convert Text to Columns Wizard.

- Select the 16 columns containing the data,

- Insert → Charts → Scatter → Scatter with Smooth Lines and Markers

- Change the title of your graph to "Name's Whistle is x.ykHz", where

Name is your name and x.ykHz is the frequency of your whistle.

Copy and paste your graph as the answer to Test #6.

Test #7 - Test Remote Control Receiver

Soldering:

No through-hole components should be soldered to the development board

in this test.

Procedure:

When you press "d" at the command prompt, the PIC will test the

remote control decoder. The IR remote control decoder sensor is able

to translate the IR energy emitted by most remote controls

into a series of logic-level pulses. This little application will

tell you the length of the first 16 of these pulses. After hitting

"d" at the command prompt, grab any handy remote control, point it

towards the dome shape on the IR decoder and press a button. You

should immediately see a series of numbers appear on your terminal.

For example, pressing the OFF button on my RoKU remote produced the

following output.

CMD> d

IR decoder test

Press a IR remote control button.

Press any key to exit.

bit high low

0: 0 4647

1: 23b4 464

2: 448 473

3: d13 47b

4: 442 46f

5: d19 474

6: 442 485

7: d0d 470

8: d1b 472

9: d12 46e

10: 457 46f

11: d27 471

12: 445 461

13: 456 471

14: 450 476

15: 44f 476

Done decoding IR packet.

Note that some cell phone emit IR signals for a variety of reasons.

Make sure that all nearby cell phones are stowed away before starting

this test, otherwise you will get unpredictable results.

Clear the PuTTY window using "z" and then enter the remote control

decoder function. Find a remote and press a button to produce a

control sequence. Make a screen

shot of the PuTTY window as your answer to Test #7.

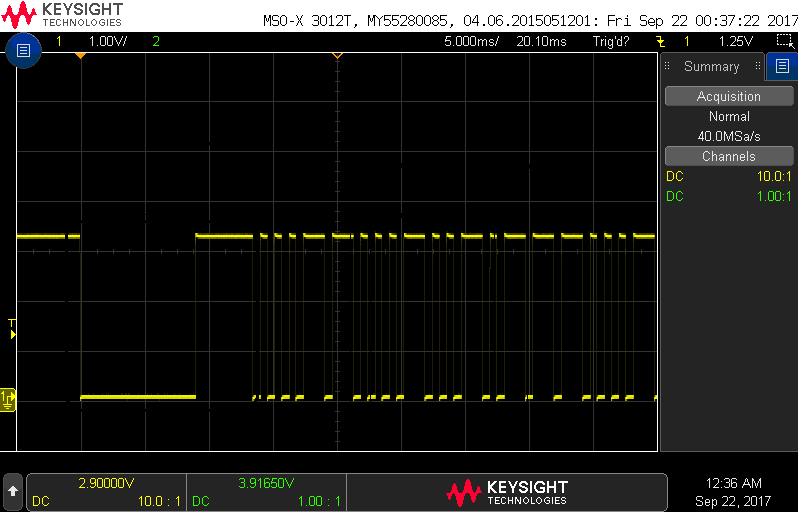

Test #8 - Test IR LED Transmission

Soldering:

No through-hole components should be soldered to the development board

in this test.

Procedure:

When you press "t" at the command prompt, the PIC will test the

IR LED and driver. When you press "t", you will be presented with

the following options - these used to control the projector in

Brown 305. The projector was moved out during the summer :(

Connect jumper over IR_TX header.

Select the index of the command to send from the following list:

0 OFF

1 ON

2 MAG+

3 PIC MUTE

4 PG UP

5 MAG-

6 PG DOWN

7 MENU

8 UP

9 LEFT

Before performing this test please make sure that you place jumpers across

the 5v jumper pins near the USB connector. This jumper will

help ensure that operating the IR LED doesn’t brown out the PIC.

Also place a separate jumper across the IR_TX header. This

jumper will enable the PIC to control the IR LED.

When you issue the "t" command from command prompt the PIC will ask

you what IR command you want to send to the projector that used to

be in Brown 305. Instead of the projector, you will use an oscilloscope

connected to the IR Remote Control Receiver output. Do this as follows.

Connect an oscilloscope probe to channel 1. Connect the ground clip

of the oscilloscope to the ground loop you soldered in for Test #5.

Use the oscilloscope probes gripper to attached to the RC0 header

pin that you just soldered in.

| Ch1 probe | RC0

|

| Ch1 ground clip | Dev board ground loop

|

| Horizontal (scale) | 10ms

|

| Ch1 (scale) | 1V

|

| Trigger mode | Normal

|

| Trigger source | 1

|

| Trigger slope | ↓

|

| Trigger level | 1.65V

|

Make sure that

- Aligning Ch 1 is on the second lowest reticule on the screen,

- Align the horizontal position at the second left-most reticule,

- Clear all menus off the bottom of the screen

[↑Back]

- Make sure the Run Control button is is illuminate green.

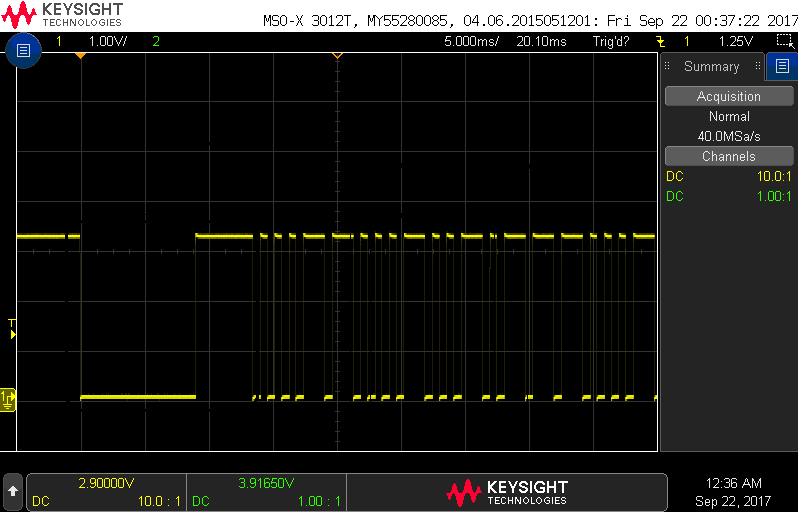

When you do this you should see something similar to the following when

you send a command using the "t" key. Note, the time base is slightly

different.

It's important to remove the jumper from the IR_TX jumper after

you complete this test. This circuit draws a lot of power and may

cause the PIC to brown-out if the jumper is left in place for other

tests.

Clear the PuTTY window using "z" and then enter the IR LED TX function.

Connect an oscilloscope as described in the instructions presented in the

PuTTY. Use a USB drive to capture an image of the captured waveform for

the numeric function corresponding to the least significant digit of your

CWID. Include the oscilloscope image as the answer to Test #8.

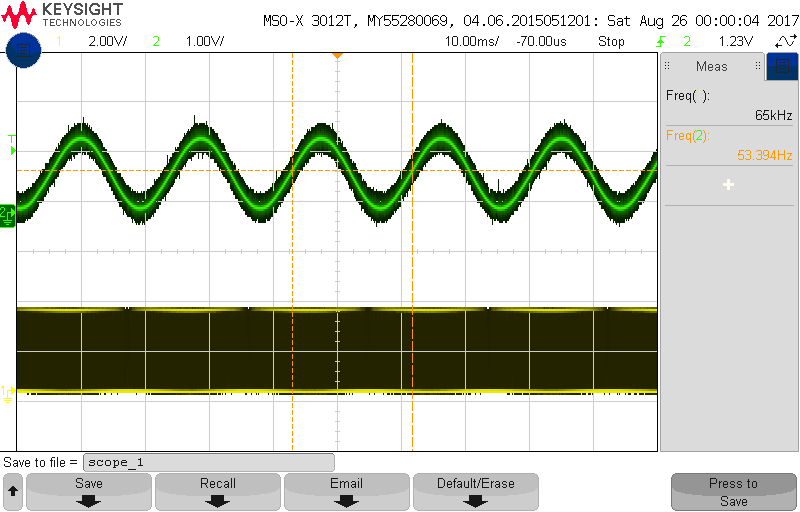

Test #9 - Test Low Pass Filter

Soldering:

No through-hole components should be soldered to the development board

in this test.

Procedure:

When you press "l" at the command prompt, the PIC will test the

low pass filter. This test will check that the Low Pass Filter

is functioning correctly. To accomplish this you will connect a PWM

channel to the LPF. You will also connect oscilloscope probe (channel 1) to

the PWM input and an probe (channel 2) to the LPF output to verify

correction operation. When you type "l" at the prompt you will see

the following instructions.

CMD> l

Low pass filter (LPF) test

Install jumper over RC2 and LPFin on header.

Connect oscilloscope channel 1 to PIC header pin C2 (vertical scale 2v/div).

Connect oscilloscope channel 2 to LPFout pin on header (vertical scale 1v/div).

Trigger on channel 2.

Set the horizontal scale to 250ms/div.

Press upper button to increase frequency.

Press lower button to decrease frequency.

Hit any key to exit.

Follow these instructions. When a jumper is placed over a pair of pins,

you can still probe the signal by

attaching an oscilloscope probe to the metal connection shown.

In order to observe the signals being generated, you need to connect MCU

pin RC2 to LPF_in pin of JP2 header with a jumper wire. After you do this

setup your oscilloscope as follows:

| Ch1 probe | RC2

|

| Ch2 probe | LPFout

|

| Ch1 ground clip | Dev board ground loop

|

| Horizontal (scale) | 250 ms

|

| Ch1 (scale) | 2V

|

| Ch2 (scale) | 1V

|

| Trigger mode | Auto

|

| Trigger source | 2

|

| Trigger slope | ↑

|

| Trigger level | 1.2V

|

Make sure that

- Aligning Ch 1 and Ch2 on the second lowest reticules

on their respective halves of the screen,

- Align the horizontal position at the second left-most reticule,

- Clear all menus off the bottom of the screen

[↑Back]

- Since the two channels are not synchronized, you may need to

tell the oscilloscope to stop refreshing the screen. To do this:

Run Control → Run/Stop (the button will illuminate red)

To resume refreshing the screen press the Run/Stop button again

causing the button to be illuminated green.

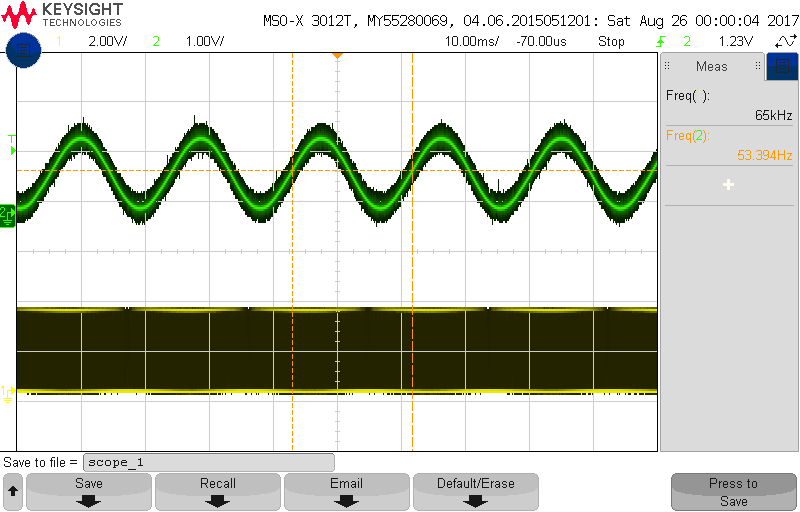

When setup, you should see something like the following on your

oscilloscope. Try pressing the up and down buttons to adjust the

frequency. Each button press should change the frequency up or

down depending on which button is pressed.

Clear the PuTTY window using "z" and then enter the low pass filter function.

Connect an oscilloscope as described in the instructions presented in the

PuTTY. Use a USB drive to capture an image of the captured waveform for

the numeric function after pressing the top button the same number of times

as the least significant digit of your CWID. Include the oscilloscope image

as the answer to Test #9.

Test #10 - Test Amplifier

Soldering:

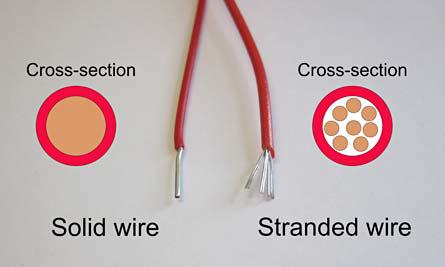

Cut off equal lengths of red and black solid core wire from the lab.

Strip off about 1/4" of wire from both ends of both wires. Use a

pair of needle nose pliers to make a small loop on one end of each

pair. Then solder this loop to the pads on the speaker.

This should look something like the following image.

Insert the exposed ends of wire from the speakers into

green terminal block and tighten the screws on the terminal block to

hold the speaker in place.

Procedure:

When you press "a" at the command prompt, the PIC will test the

audio amplifier. The following instructions tell you how to configure

the development board.

CMD> a

Amplifier test

Press any key to exit.

Connect PIC pin C4 to LPFin pin using a jumper wire.

Place a jumper over the LPFout/AMPin jumper.

Place a jumper over JP1 next (it's next to the USB port).

Connect the speaker to the green terminal block.

Press the upper button to play the next note from a song.

Press any key to exit.

The development board comes equipped with a National Semiconductor

LM4862 audio amplifier which will drive the mini speaker.

While the button is held down, the note will play. Releasing the button

moves to the next note which is played when the button is pressed.

You must place a jumper over the 5V jumper when performing

this test, otherwise your PIC will brown-out. This will cause

unpredictable behavior.

It's possible that your development board will brown-out during this

test even with 5V jumper in place. This can happen because the speaker draws

so much power that the Vcc level on the development board drops below

the minimum needed to keep the PIC operating

correctly.

Take a picture of your speaker with soldered wires and include it

as the answer for Test #10.

Test #11 - Test RGB LED

Soldering:

No through-hole components should be soldered to the development board

in this test.

Procedure:

When you press "c" at the command prompt, the PIC will test the

RGB LED, and you will receive the following instruction on where

to place three colored jumper wires in your kit. You may can separate

the jumper wires by peeling them away from one another.

CMD> c

RGB LED test

Connect RC2 to R.

Connect RB0 to G.

Connect RB5 to B.

Hit any key to exit.

When you run the RGB test you should note that the

LED cycles through the rainbow colors. Its not an entirely smooth

progression, but should be fairly close.

Take a picture of your development board with all three jumper wires

attached and the RGB LED displaying yellow as your answer for Test #11.