EENG 393

In Lab 13 - Supply Chain

Requirements

There is no turn-in associated with this inLab. You may need some of the tutorials

linked below to help with the asssmbly of your uSupply.

Objective

Case Study

Read the Sparkfun article about their purchase of a batch of

counterfit

ATmega328 chips.

Reflow Skillet

Hot Air Rework Station

Wire Tinning

Splicing wires

Make How To Splice Wires to NASA Standards

How to Mesh Splice

Crimp tool with Dupont Connector

JST connectors

A wire harness is a collection of wires with connectors at each end.

Wire harnesses are often a secondary consideration when designing a

PCB, but in fact there is a lot to consider.

- Gender

- While the gender of some connectors is obvious,

others can be confusing. Regardless, in order to make an electrical

connection, you need a male connector plugged into its female counterpart.

- Polarity

- When a connector can only be positioned in one

orientation to make a connection, it is said to be polarized. There are

a lot of good reasons for polarized connectors, but they are often a little

more expensive and less reliable than their non-polarized counterparts.

- Pitch

- The number of contacts per inch is called the pitch.

Imperial units prevail in most circles with 0.1" being the most common.

In this section we are going to walk through how to build a simple

4-wire harness to power your 556 timer PCB and gain access to the signals.

There will be four main parts to our wire harness:

- Wire - stranded wire is more flexible. As a result stranded

wire is preferred when building a wire harness. In order to work

with a wire, we will need to strip the insulation off the wire.

I purchased a pair of cheap Knipex Self Adjusting Insulation

Strippers and I am as happy as a clam. Do yourself a favor and

get some.

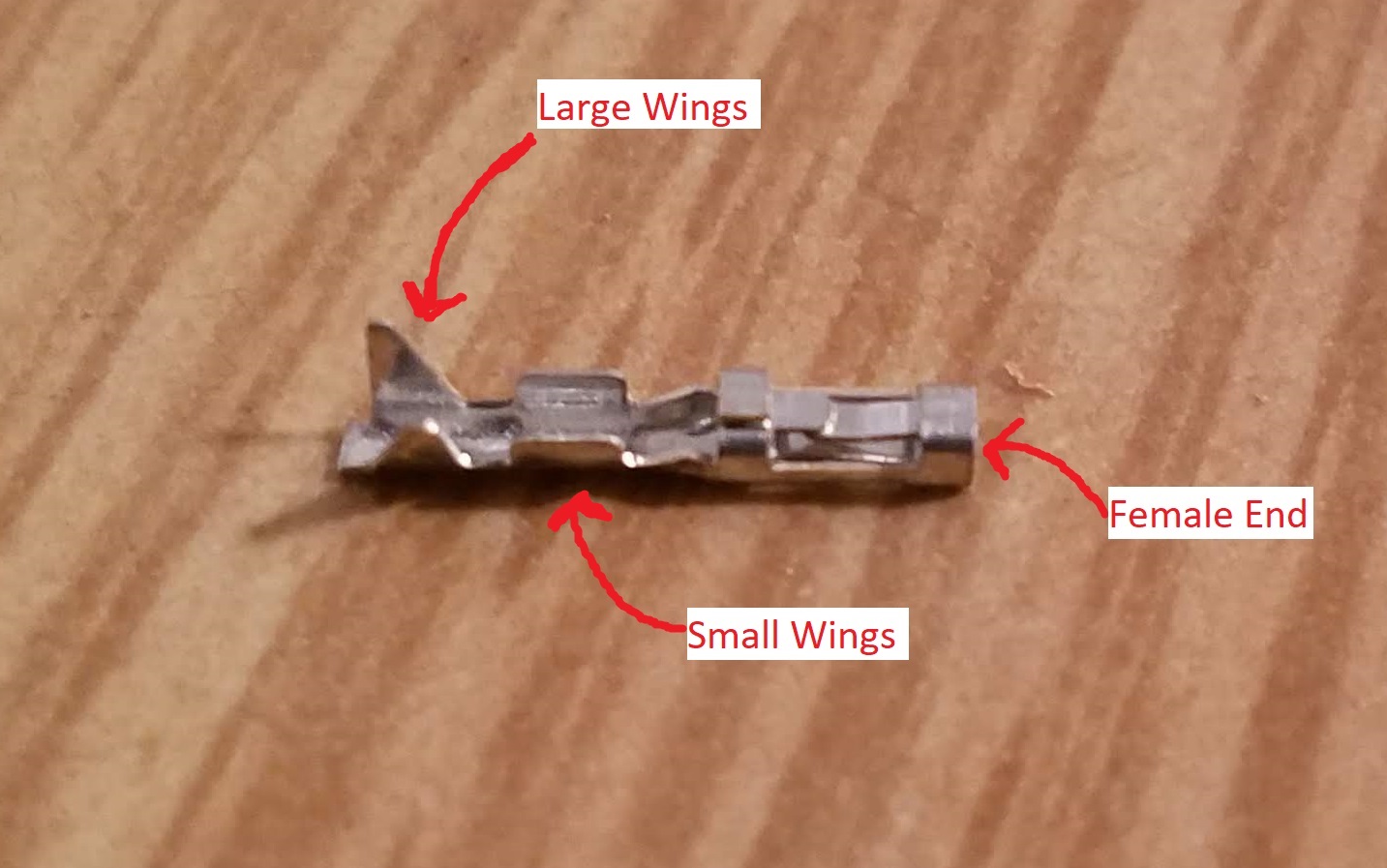

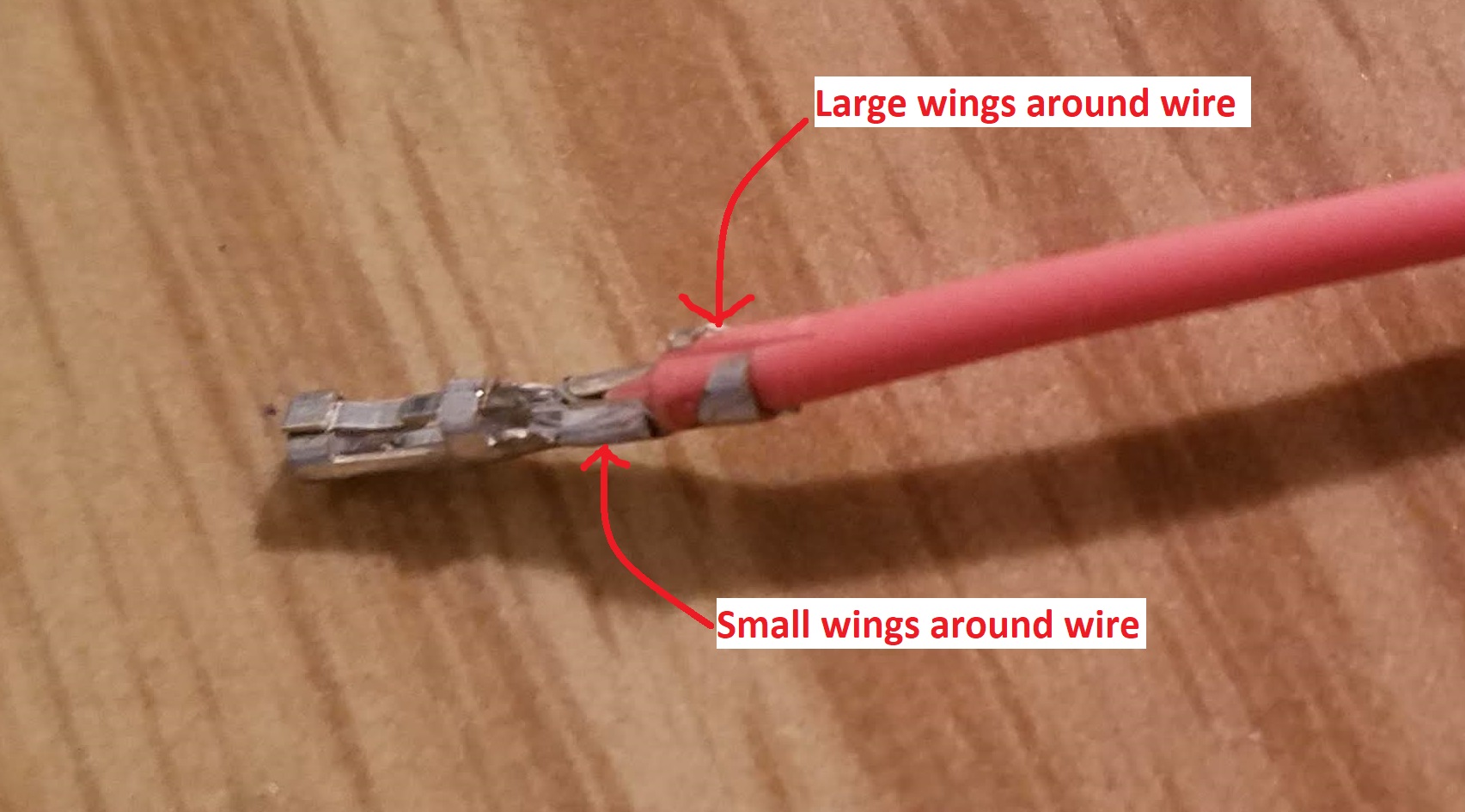

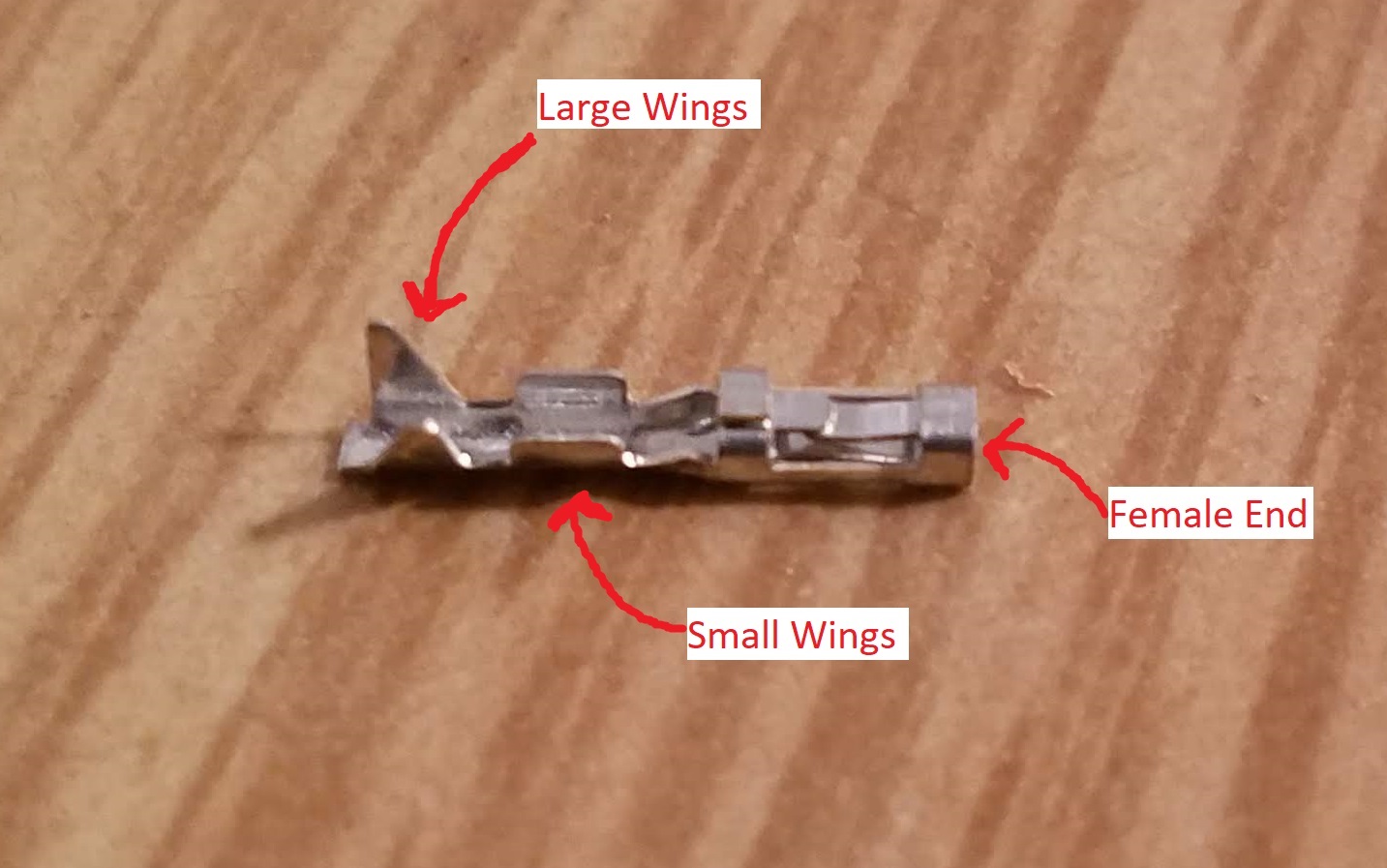

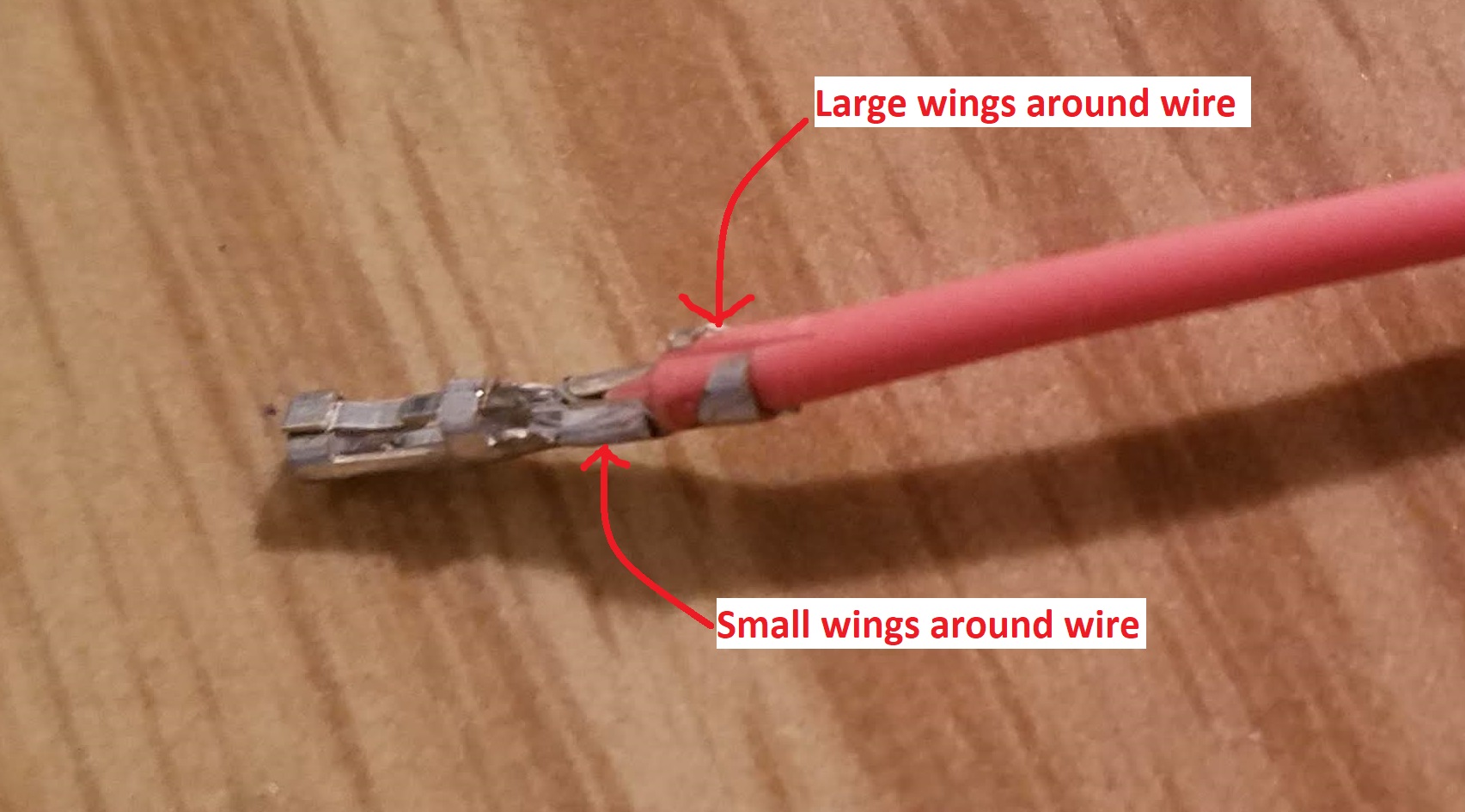

- Crimps - these are the small metal bits that connect to the wire.

The crimp has two sets of "wings", the larger pair at the rear of

the crimp hold the insulation of the wire, the small pair towards

front hold the conductive wire.

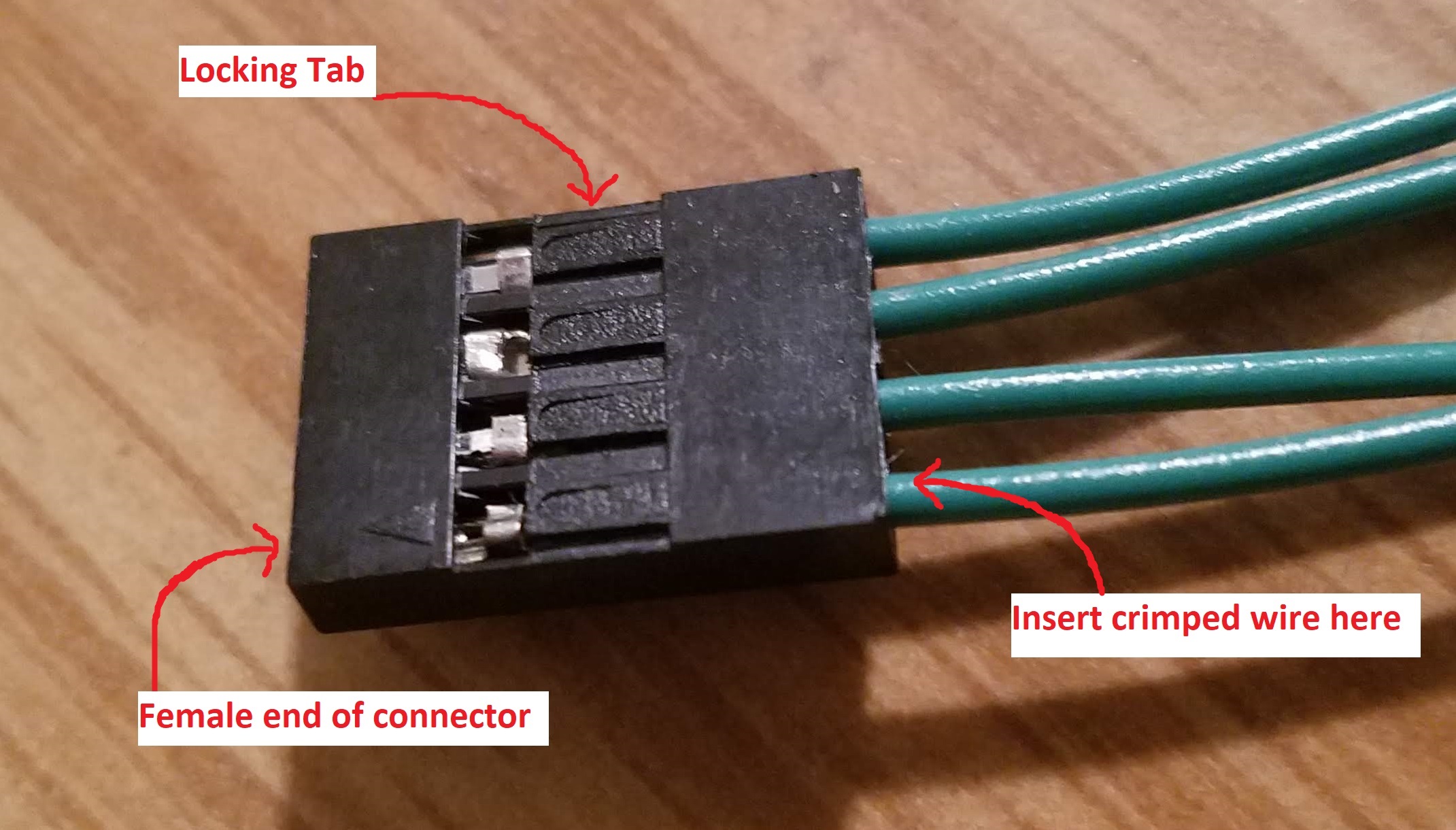

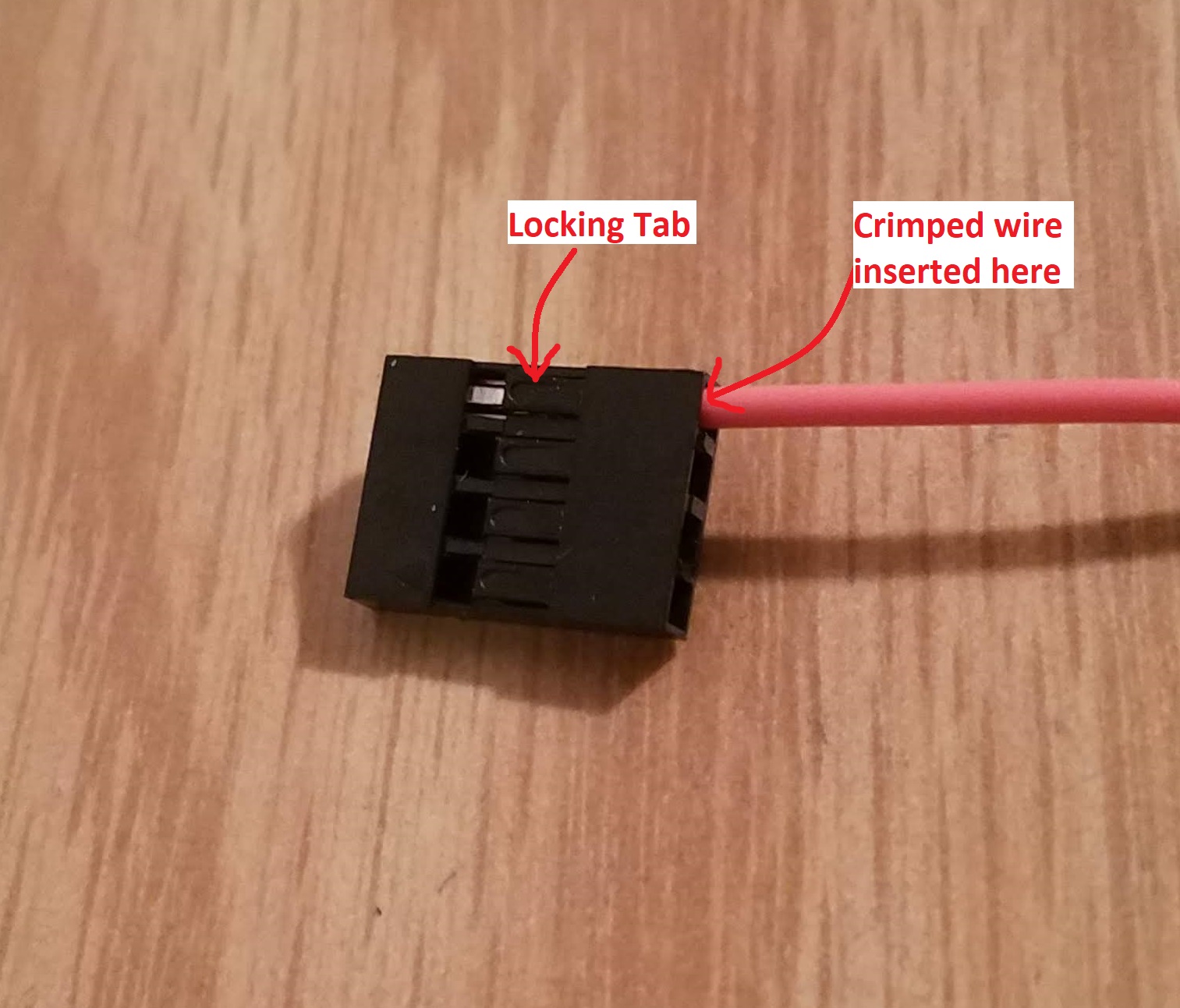

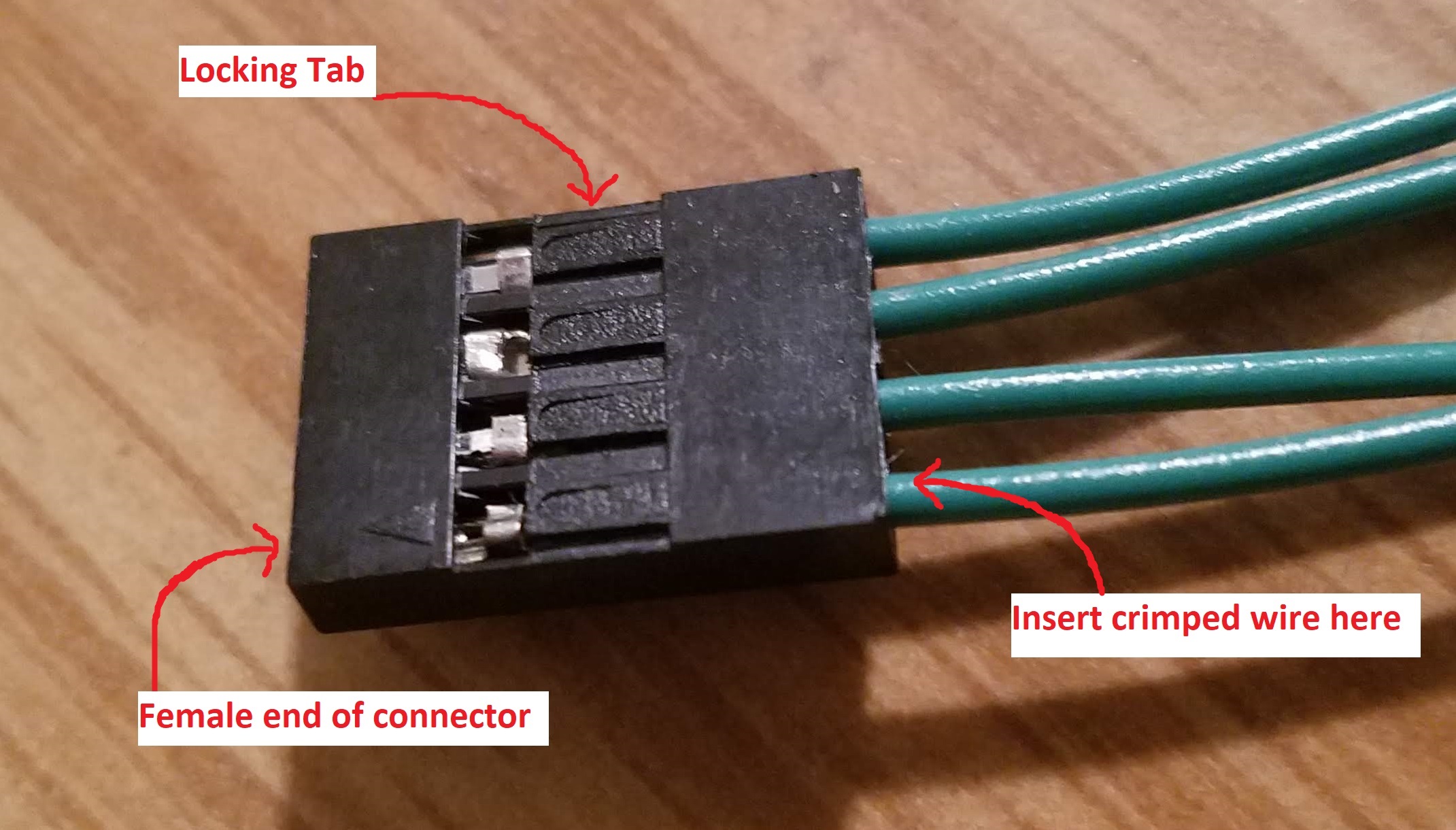

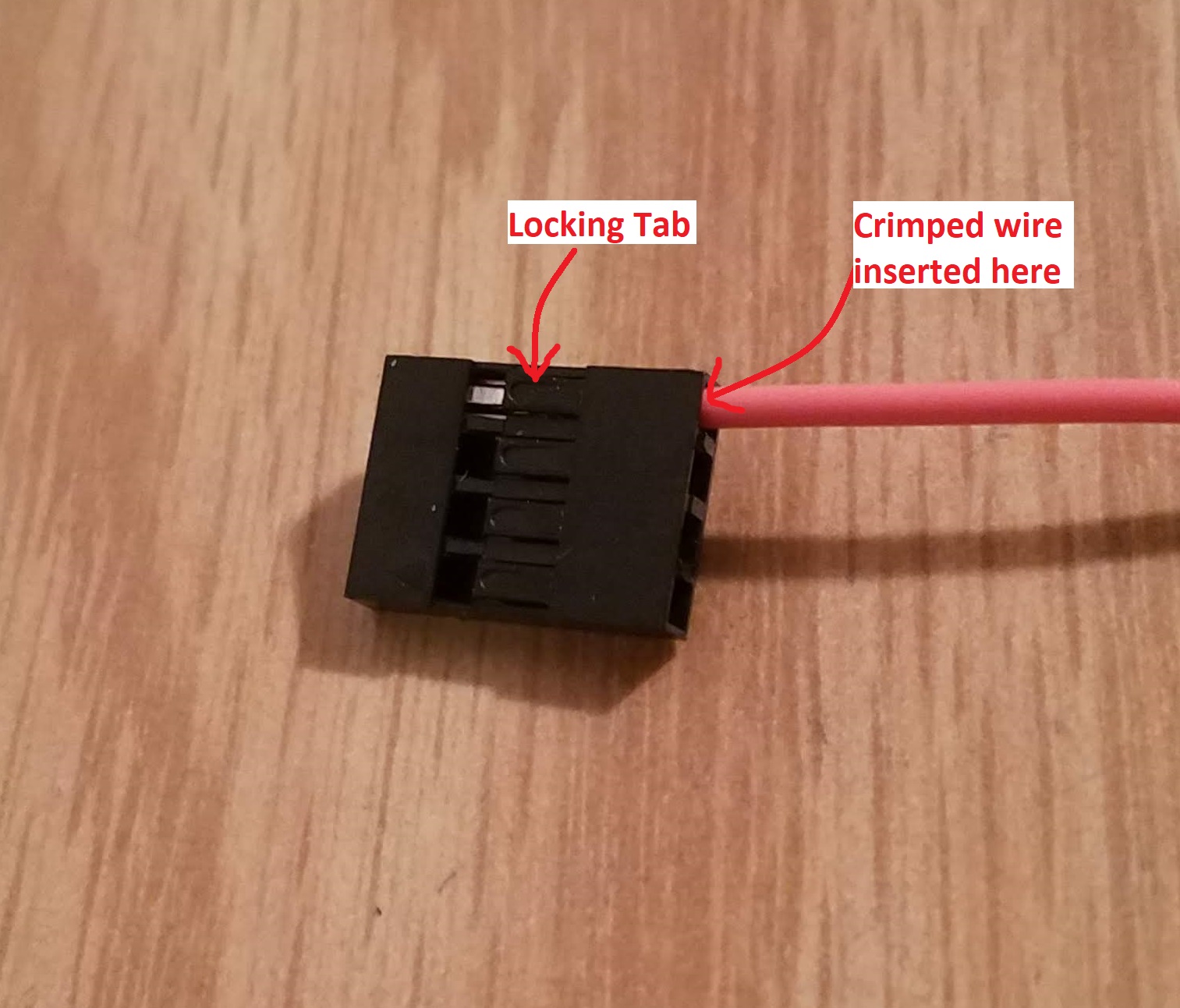

- Plastic housing - this holds several crimps in place so they

can be connected as a single unit. The crimps have a little tab

which locks it into place when the crimp is inserted into the

housing.

To create a harness, you will need to attach the crimp to the wire using

a crimp tool. The crimp connector has several opening to

accommodate different gages of wire. My crimp tool has

three openings, one to accommodate 24-28 gauge wires, one for 22-20 gauge

and one for 20-18 gauge. My tool is ratchet, meaning that as the handles

are squeezed together, the tool incrementally closes. Meaning that if the

jaws are brought together to a certain distance, the jaws will remain

there until the jaws are brought all the way together or the secret

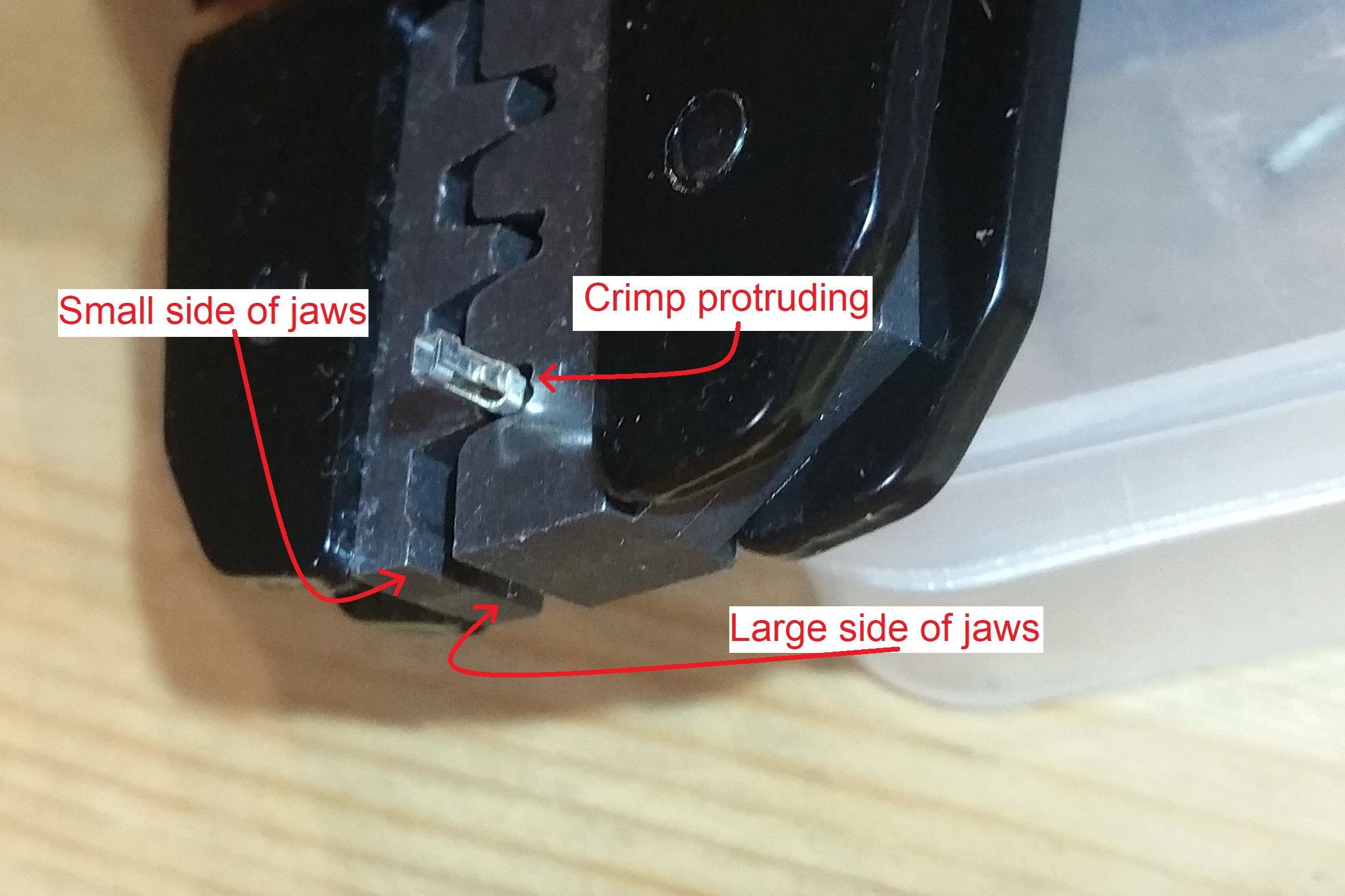

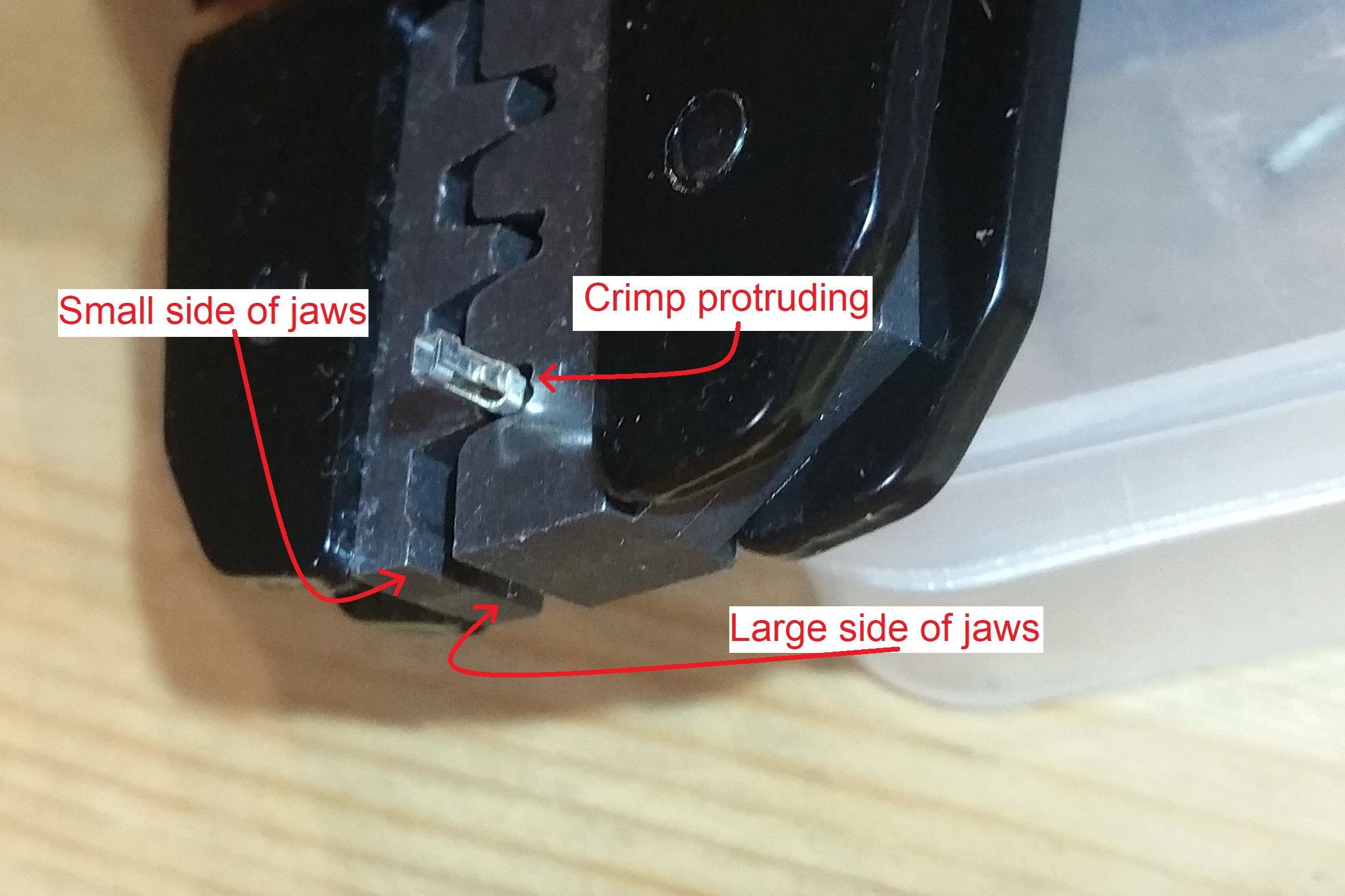

switch is pressed. The jaws are not uniform across their width. Close

inspection reveals that both the upper and lower jaws consist of two

plates. These two plates form two regions across the width of the

jaws, a small side and a large side. When the jaws are fully closed,

the small side of the jaws leave the smaller side opening smaller than

the opening left on the large side. The first image below shows the small

side of the crimp tool, while the second shows the large side.

- Strip 2-3mm of wire

- Position the crimp in the crimp tool - 3 clicks is enough to

partially close the crimp tool and still have enough room to insert

the crimp into the 28-24 opening.

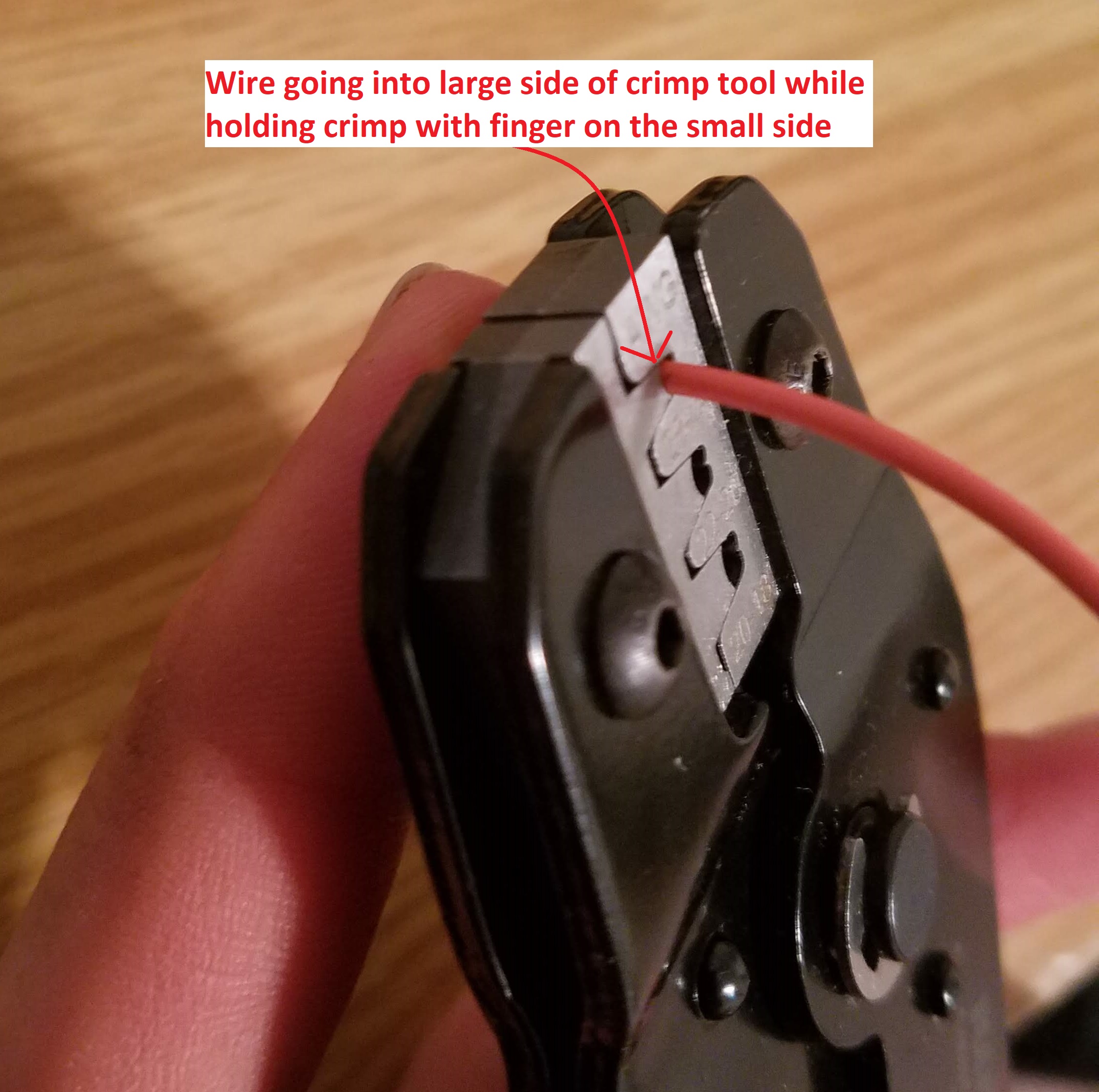

- Insert the stripped end of the wire into the crimp tool.

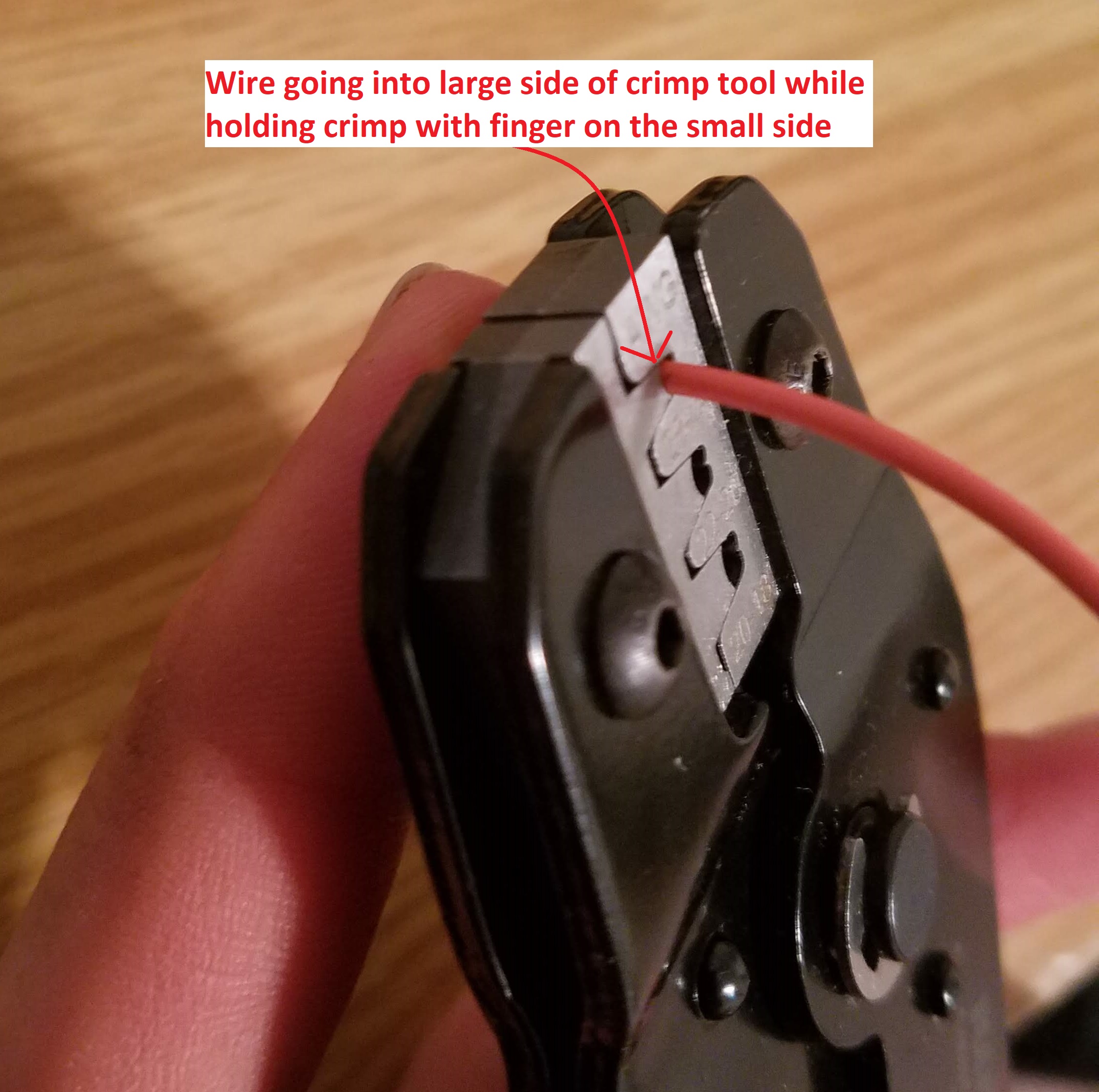

This is the msot difficult and critical step. I've found that

while holding the crimp tool in my left hand, I can manuever

my trigger finger on my left hand around and hold the female

portion of the crimp into the small side of the crimp tool's jaw.

You cannot alllow any portion of the female end to get in the

crimp tool's jaw. At the same time, you need to insert as much

of the crimp as you can into the crimp tool.

Only when I am happy with the crimp position and my finger

placement, do I turn the crimp tool over to look at the large

side of the crimp tool jaws. I then insert the stripped end of the

wire into the end of the crimp which is a few millimeters inside

the large side of the crimp tool. You need to insert the wire so

that the stipped wire is well into the inner wings but not into the

female socket on the end of the crimp.

- Crimp and inspect - Once you have the crimp and wire positioned

do you crank down on the handles. If you ahve done everything

correctly you will get a sturdy crimp connection to the wire.

- Insert crimped wire into plastic housing

You can remove the crimped wire from the harness by plucking up the

barb on the plastic housing.